ABOUT ACL

For over 70 years precision engine bearings have been manufactured in Launceston, Tasmania, Australia.

During this time ACL has been a major OEM supplier to the Australian & International automotive industry, whilst providing an extensive replacement product range for the global aftermarket.

Today ACL produces one of the largest aftermarket range of engine bearings and has a global reputation for robust metallurgy, quality, precision, innovation and performance.

ACL has a long and rich history in motorsport – it is in our DNA. The ACL RACE Series Performance Engine Bearings of today has a strong pedigree in motor racing that traces its roots back to the 1960’s with the manufacture of engine bearings for use in the world conquering Brabham Formula 1.

Further experience in the Australian Supercars Championship, drag racing, speedway, drifting & rally with its range of RACE Series Performance Engine Bearings being the first choice for discerning engine builders the world over.

The ACL RACE Series Performance Engine Bearing offering covers over 200 varied engine applications covering a wide range of performance engine bearings for Australian, American, Japanese, Korean & European applications. The range continues to expand to cover new engine releases.

The company has a high degree of vertical integration encompassing: tooling & product design, bearing strip manufacture, tooling & machine manufacture as well as the complex manufacturing processes & systems required to produce the final product.

ACL's Business Management Systems hold the internationally recognized ISO9001: 2015 Quality Management System, ISO14001: 2015 Environmental Management System & ISO451001: 2018 Occupational Health & Safety Management System certification.

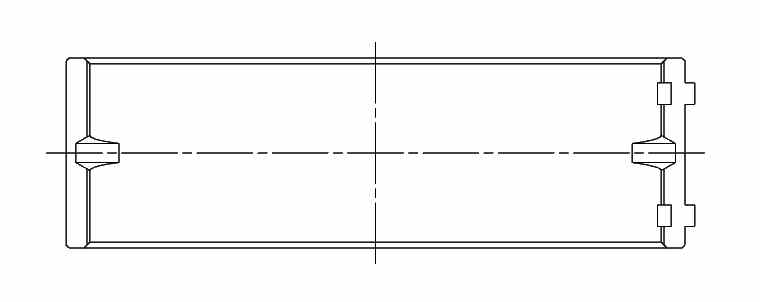

Description: BMW S65B40 3999cISc V8 DOHC 4v

Capacity: 3999 CC

Cylinders: 8

Bore Size: 3,622 in / 92 mm

Stroke: 2,9606 in / 75,2 mm

FEATURES

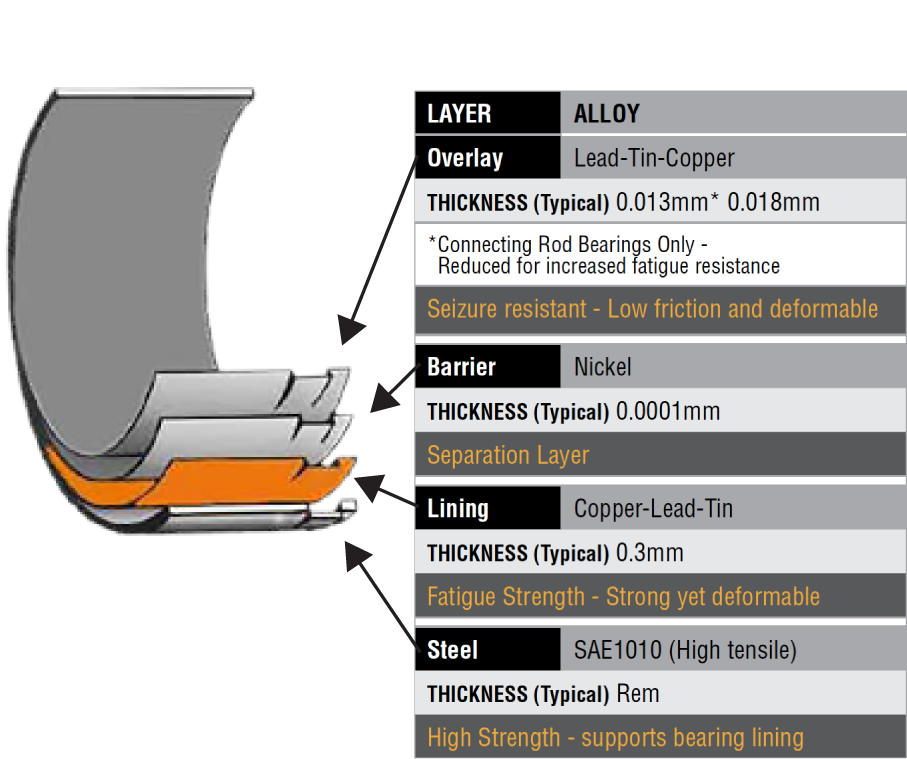

- HIGH STRENGTH OVERLAY PLATE with reduced thickness for improved fatigue properties

- HARDENED STEEL BACKS on all rod bearings to improve the support of the bearing lining and assist with bearing retention in the housing.

- INCREASED CRUSH for improved bearing retention

- ELIMINATION OF FLASH PLATING on the back of the bearings to improve heat transfer through the bearings and to maximize the grip between the bearings and its housing.

- INCREASED ECCENTRICITY to compensate for bore distortion at high rpm and to assist in the formation of hydrodynamic oil films.

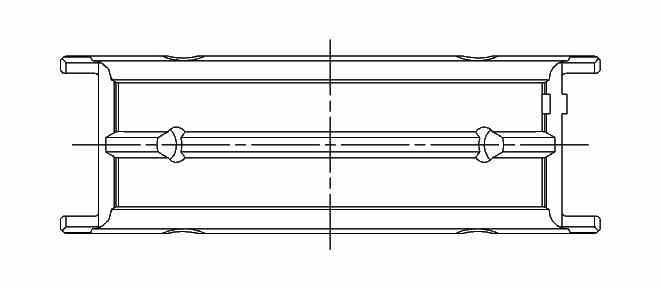

- 3/4 GROOVED MAIN BEARINGS to optimize bearing load carrying surface area and oil flow to the conrod bearings.

- TIGHT CONSISTENT WALL TOLERANCES to help you maintain consistent clearances.

- ENLARGED ID CHAMFERS on bearing edges where required to accommodate large fillet radius on performance crankshafts.